The Textile Welding Revolution in the Medical Sector: Innovation and Efficiency

In the quest to improve quality and efficiency in the medical sector, textile welding is emerging as a revolutionary technique transforming how garments and medical devices are made. In this article, we will explore in detail what textile welding is and how it is positively impacting the industry, with a particular focus on the solutions we offer from Artesana de Clofent.

What is Textile Welding?

Textile welding is an innovative process that allows fabrics to be joined without the need for traditional seams. Instead of using thread and needle, different methods that generate heat and pressure are employed to melt the fibers of thermoplastic materials, thus creating a solid and durable bond between the fabrics.

Advantages of textile welding in the medical sector

By adopting textile welding in the manufacture of garments and medical devices, a number of significant advantages are obtained:

- Better bonding and strength: Textile welding ensures a stronger bond between fabrics, drastically reducing the chance of tears or tears in the seams. This is especially crucial in medical garments that require strength and durability to withstand repeated use and demanding conditions.

- Reduced costs and labor: By eliminating the need for traditional seams, the time and cost associated with the tailoring process is reduced. In addition, being an automated process, manual intervention is minimized, which in turn decreases the possibility of errors and increases the efficiency of the manufacturing process .

- Shorter processing time: Textile welding allows for faster production of garments and medical devices, resulting in a shorter lead time for customers. This rapid response is critical in medical settings where the immediate availability of equipment and supplies can make all the difference in patient care.

- Higher quality: thanks to the precision and consistency of the textile welding process, superior quality is guaranteed in the garments and devices manufactured. This results in end products that meet the highest standards of safety and performance, which in turn inspires confidence in both medical professionals and patients.

Textile Welding Methods

There are several methods of textile welding, each with its own characteristics and applications. Among the most common are:

- Ultrasonic welding: This method uses high-frequency sound waves to melt the fibers of thermoplastic materials, creating a solid bond between the tissues. It is effective at bonding multiple layers at once, making it ideal for making medical garments.

- Impulse welding: This involves the use of a thin strip of metal to transmit heat through the fabric, melting the fibers and creating a strong bond. This method offers advantages in terms of energy efficiency and is suitable for applications where precision and control are required.

- Radio frequency welding: Similar to ultrasonic welding, this method uses radio frequency waves to generate heat and pressure, melting the fibers of thermoplastic materials and creating a solid bond. Although the welding time may be longer than with other methods, it offers high-quality and accurate results.

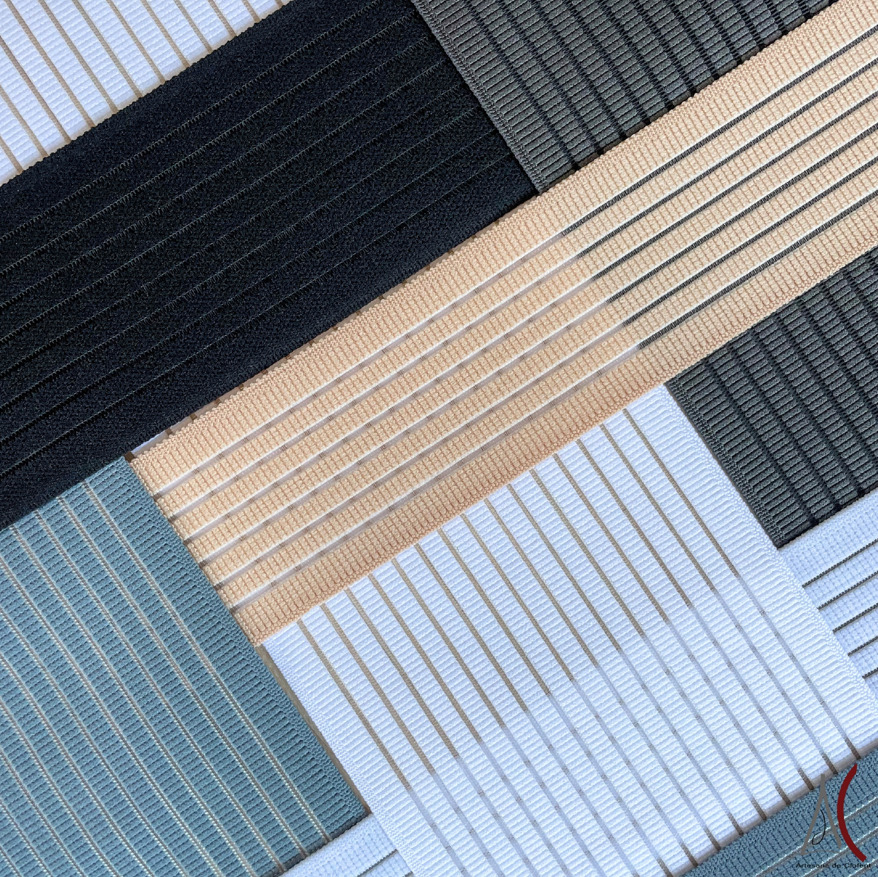

Fabrics adapted to textile welding by Artesana de Clofent

At Artesana de Clofent, we understand the importance of using fabrics that are compatible with textile welding processes. That is why our fabrics are designed to guarantee the quality and durability of the final garments, meeting the specific needs of different pathologies and medical applications. Contact us if you want more information.

In summary, textile welding represents a significant innovation in the medical sector, offering a number of benefits ranging from increased strength and durability to increased efficiency and quality in the final products. With its commitment to excellence and innovation, Artesana de Clofent is at the forefront of this revolution, providing high-quality textile solutions that meet the demands of the demanding medical market.